Multi-functional, Adaptive and Sustainable Structures Lab

We are pushing the boundaries of what’s possible using engineering materials and structures to enable multi-functionality, and using this knowledge to tackle societal challenges in healthcare, resilience and net zero.

Overview

Most natural organisms show fascinating mechanical versatility when they interact with their environments. Human-made structures, however, lack adaptability and are normally designed to meet a specific load carrying requirement. This makes them are far less efficient than natural materials.

The aim of our research is to create novel, smart materials and structures that are lightweight, sustainable and capable of performing multiple tasks.

Our research encompasses the whole development cycle:

- Design (AI-guided design; topology optimisation)

- Material (smart materials, sustainability)

- Manufacturing (additive manufacture, nano-manufacturing

- Testing (novel testing methods).

Projects

Rapidly de-stiffening windscreens for reduced fatalities

Every year, 1.2 million people die and up to 50 million globally suffer non-fatal injuries as a result of road traffic accidents.

In the UK, over half of all fatalities relate to pedestrians and cyclists, and up to 51 per cent of serious head injuries happen when the head has impacted the windscreen.

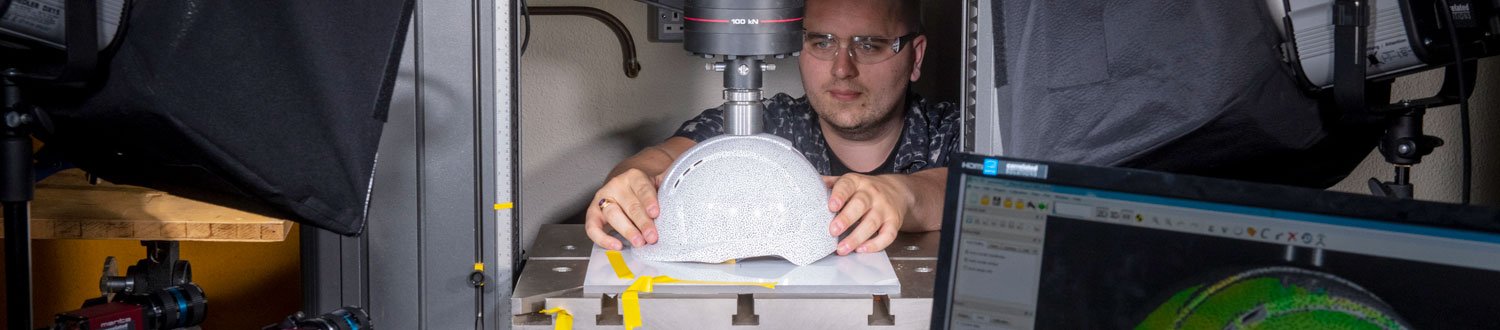

In a research project funded by EPSRC, we are working to reduce the severity of head injuries in pedestrians and cyclists when accidents happen. We have successfully developed and demonstrated transparent structures which, when activated, soften their structural response in the most critical areas of windscreens.

The rapid de-stiffening capability we have developed is based on a novel manufacturing technique which creates transparent thermal heaters capable of rapid heating (50°C/s). This enables the laminated glass to reduce stiffness in a very short space of time.

In addition to windscreens, this technology could be utilised in soft robotics, morphing and deployable structures.

Multifunctional flooring design for independent living

There are currently 12 million people aged 65 and over, and this is projected to grow to 17.5 million by 2040. Falls and their related injuries are one of the major barriers to healthy ageing. In the UK, fall-related injuries are estimated the cost the NHS more than £2.3 billion a year, and according to the World Health Organization, falls are the leading cause of injury deaths in people aged 65 and over, with half occurring in their own home.

One of our key areas of research is to develop novel multi-functional flooring with passive fall prevention, detection and protection in one integrated solution. This is the focus for a current project supported by EPSRC and NIHR, in collaboration with University of Portsmouth. In this project, we are creating design maps to capture the trade-off between different required functionalities of flooring by systematic exploration of the whole design space. This design space can then be exploited for multifunctional flooring and enable designers to provide an optimal solution for a particular care setting.

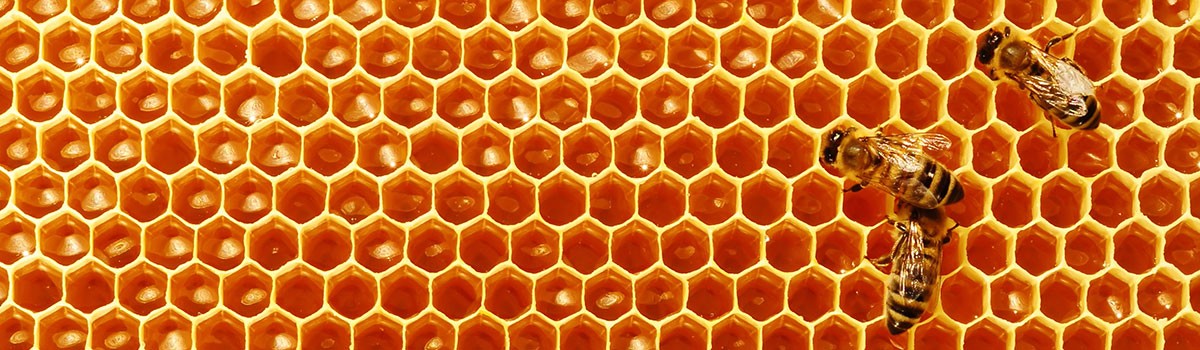

Lattice structures for lightweighting

We are exploiting the holistic benefits of lattice structures, inspired by those found in nature, to create lightweight ‘programmable’ materials. These semi-hollow structures weigh less than their solid equivalents and, when combined with active materials, enable us to create materials and structures with a wide range of properties.

(‘Active materials’ are defined as ones which show mechanical response when subjected to non-mechanical stimuli such as thermal, electrical, magnetic, optical or even changes in humidity of pH.)

Improving the sustainability of advanced materials

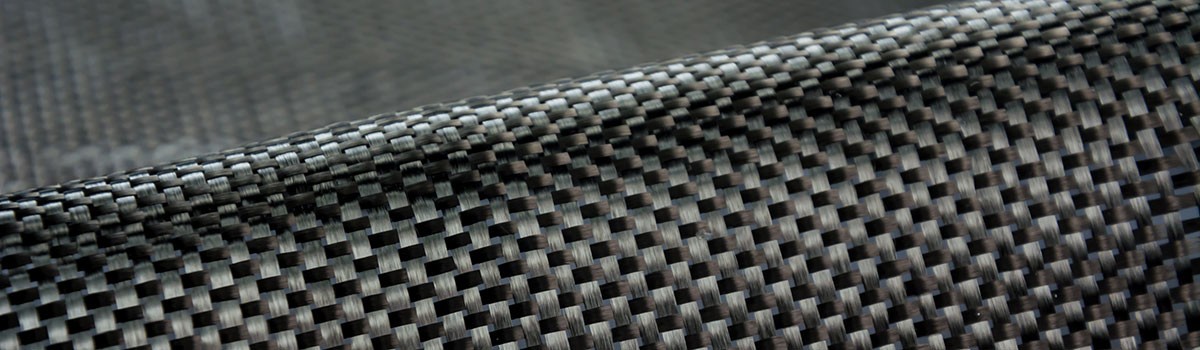

The global demand for carbon fibre reinforced polymers (CFRP) has tripled in the last decade, with increasing use in sectors such as sporting goods, medical pressure technologies and vessels.

This rapid growth has caused a major environmental challenge in terms of related wastes including production waste (offcuts and scraps of cured composites which represent up to 40 per cent of the total materials) and end-of-life components. Carbon fibres are the highest added-value component in a composite but, they are also the most environmentally impacting.

Currently, there is a very limited market for the reclaimed carbon fibre. Addressing this issue, we are designing for multi-functionality in second-life applications, with the aim of creating demand for CFRP recyclates, and achieving circularity in the CFRP life cycle. This project is supported by EPSRC, the National Composites Centre and High value-Manufacturing Catapult.

Adaptive structures using shape memory alloy

Integrating carbon fiber reinforced polymer (CFRP) with shape memory alloy (SMA) has opened the door to the development of lightweight, adaptive materials with a myriad of promising applications. Among these are aircraft morphing wings that can adjust their shape in response to different flight conditions, improving aerodynamic efficiency.

Wind turbine blades that can alter their configuration according to wind speeds, ensuring optimal energy capture. Robotic arms that are more versatile and adaptive to varied tasks. And deployable structures for satellites that can compact for launch and expand once in orbit. By merging the strength of CFRP with the adaptability of SMAs, we are crafting the next generation of adaptive structures primed for efficiency and versatility across numerous industries.

Meet the team

If you’re interested in finding out more about our research, or have a query, please contact Dr Iman Mohagheghian at i.mohagheghian@surrey.ac.uk.

Dimitrios Charaklias

Postgraduate Research Student

Dr Weijian Ge

Research Fellow in Multifunctional Structures for Flooring

Dr Iman Mohagheghian

Associate Professor (Reader) in Mechanics of Materials

Parham Mostofizadeh

Postgraduate research student

Dr Dayuan Qiang

Electrical Machine Engineer (KTP Associate)

James Smith

Postgraduate Research Student

Henry Yu

Postgraduate Research Student