Advanced manufacturing

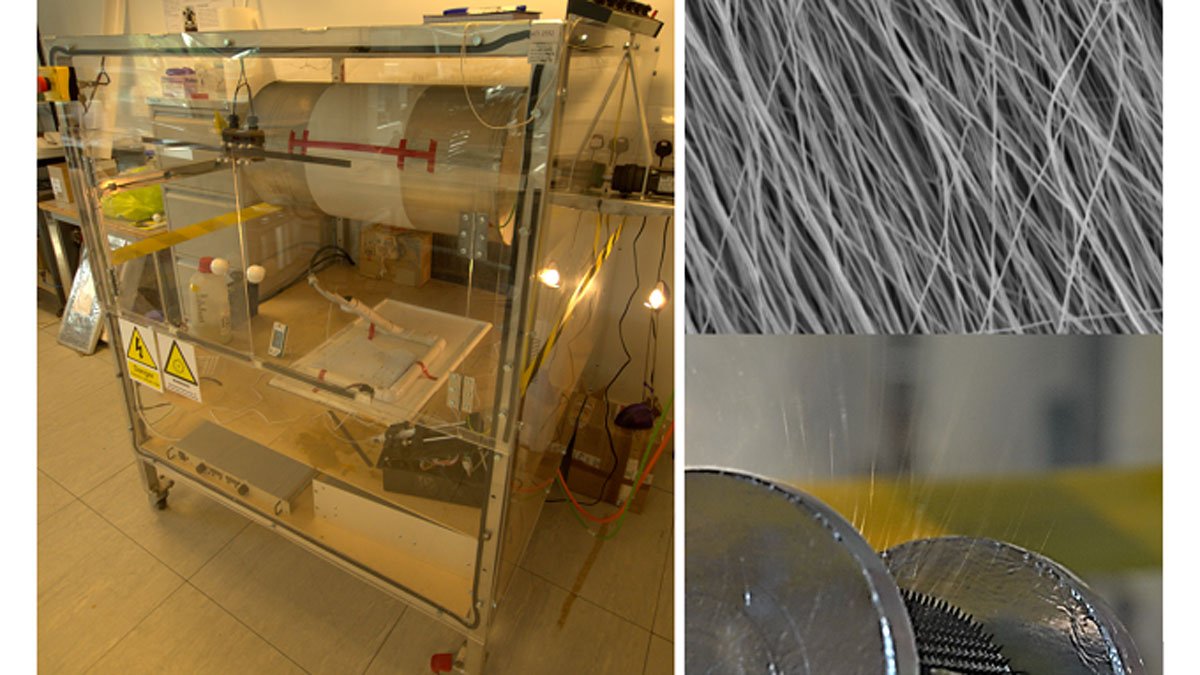

The Advanced Technology Institute (ATI) is home to two electrospinning systems, a formulation design and testing small rig and a large-area rig capable of producing nanofibres in any desired orientation, up to areas as large as 0.8 x 1.2 m.

Nanofibres

Polymer nanofibers can make composites tougher and stronger and can provide excellent pollution and viral filtration. Nanofibre mats make superior tissue scaffolds and can be used to make ultralight sponges, with massive surface areas. Polymer molecules are forced into alignment in nanofibers and thus can lead to significant electrical activity, eg. Piezoelectricity, for use in energy harvesting and sensing applications. Nanofibre mats are flexible, breathable and can transform a hydrophobic polymer into a hydrophilic film.

Electrospinning

Electrospinning is a manufacturing method that uses a high electric field to pull a thin jet of polymer ink out of a droplet from the end of a syringe needle; this phenomenon was first studied by Sir GI Taylor 1964 (the so-called Taylor cone).

The nanojets are then attracted to a collector (e.g. a rotating collector) and they begin to dry and whip before they land on it as nanofibers. These fibres are typically of 100-500 nm in diameter, are continuous and can be aligned simply by speeding up the collector.

Our rigs have built-in air extraction and HEPA filtration unit, and this allows for the incorporation of any nanomaterial within the electrospinnable solution, providing the ability, for example, to produce large areas of aligned carbon nanotube sheets.

We currently produce carbon nanotube sheets and wires for lightweight conductive cables and we manufacture nylon-graphene veils for improving aerospace composites and giving them further functionality. We also manufacture piezo-electric nanofibers mats for textile sensors and textile energy harvesting solutions.

Figure 1: Large area electrospinning rig can use single-needle, multi-needle spinnerets or needle-less arrangements to deposit films of aligned or non-aligned polymer nanofibers.

Selected publications

Forouharshad, M., King, S. G., Buxton, W., Kunovski, P. and Stolojan, V. Textile-Compatible, Electroactive Polyvinylidene Fluoride Electrospun Mats for Energy Harvesting. Macromolecular Chemistry and Physics.

King, S. G., Castaldelli, E., McCafferty, L., Silva, S. R. P. and Stolojan, V. 2018a. Micro-Centrifugal Technique for Improved Assessment and Optimization of Nanomaterial Dispersions: The Case for Carbon Nanotubes. Acs Applied Nano Materials, 1, 6217-6225.

King, S. G., McCafferty, L., Stolojan, V. and Silva, S. R. P. 2015. Highly aligned arrays of super resilient carbon nanotubes by steam purification. Carbon, 84, 130-137.

King, S. G., Stolojan, V. and Silva, S. R. P. 2017. Large area uniform electrospun polymer nanofibres by balancing of the electrostatic field. Reactive and Functional Polymers.

King, S. G., Terrill, N. J., Goodwin, A. J., Stevens, R., Stolojan, V. and Silva, S. R. P. 2018. Probing of polymer to carbon nanotube surface interactions within highly aligned electrospun nanofibers for advanced composites. Carbon, 138, 207-214.

Pozegic, T. R., King, S. G., Fotouhi, M., Stolojan, V., Silva, S. R. P. and Hamerton, I. 2019. Delivering interlaminar reinforcement in composites through electrospun nanofibres. Advanced Manufacturing-Polymer & Composites Science, 5, 155-171.

US Patent Application for An Electrospinning Device and Configuration Method (Application #20180223451).